www.breadaddiction.co.uk.

www.getbrewing.uk

www.beerproject.be

www.toastale.com

Brew house efficiency

Sunday 31 January 2016

Saturday 30 January 2016

Making beer out of bread

- It was while watching Jamie and Jimmy’s Friday Night Feast that I found myself watching a story about two guys in Belgium making beer out of waste bread. We all know that food waste is bad, but I didn’t know that bread is one of the highest products being wasted. Their theory was that if they could turn waste bead into beer, that would be good. So they went out and did it.

- The program I was watching is entertainment with food as the theme. Therefore it wasn’t a technical description on how to brew bread into beer. However they talked about starch, enzymes, replacing grain with malt, efficiency was nearly as good, etc etc. I thought let’s try a home brew version.

- I would like to say that my motivation was to save the planet, while saving the plant is fine upstanding thing to do, the truth is, I thought it would be pretty cool if I could do it.

- A bit of googling later, I couldn’t find anyone that has written a home brew out of bread recipe. As far as I can see only the Belgium Beer Project, and with their help, a Brewery in Hackney making a beer called Toast ate making beer out of bread.

-

- The bread 4 sour dough loaves

- So with my vast experience of 7 full mash beers under my belt, all a variation of Fullers ESB, I decided my 8th brew would be a Belgium made out of waste bread. I reread some articles on enzymes and Belgium beers etc and I decided to go for a Kwak like recipe, but aim for a 6.5 rather than a 8.5.

- While reading this, please don’t think that your are reading a “how to” manual. I’m a bit of a nurd, so when attempting something I will generally read up on the subject, some of which will stick, some won’t. But at some point I will just say “screw it this, just do it”. This is no exception. In this case there isn’t a go to page on a homebrew web site to unravel the mysteries of brewing beer from bread, so I screwed it and just did it….

- My basic method and equipment are on previous posts. I have just about dialled in my brew. 16l mash water, 16l sparge. I use the beer smith app in the iPad. The last couple of brews have come in spot on OG and fermentation water target of 19l.

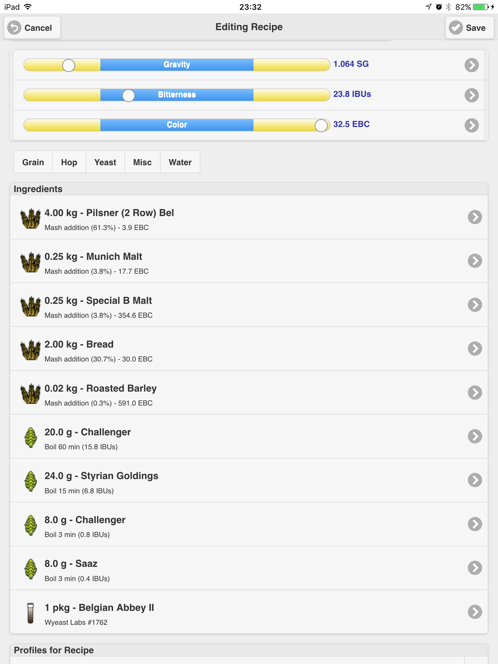

- I was was well organised for this brew. Yeast starter using 100g light DME in 1l water. Grain and bread Ingredients measured the day before, 32l of water split in two open containers to let the chlorine out, etc. I’ll post recipe below. Everything I was reading pointed to bread at 30% of grain bill, in this case 2kg.

Getting the bread ready to mash - Where the bred came from? I talked over the idea with Alan at getbrewing.uk in Portsmouth.. He suggested “next door” as a source of bread. Next door are www.breadaddiction.co.uk. I went in and asked if they had 3kg of stale bread, I think though thought I was slightly mad when I explained what I wanted it for. However they were kind enough to to give me 4 loaves of Artisan bread for free. Plus a brought a fresh one to eat.

- Having talked a good game, and now I had the bread, I had to get it done. I prepped the bread by cutting it into chunks, and drying it out in the oven for a couple of hours on a low heat. No, I have no idea if this is the correct thing to do, it was hinted at on the TV show.

- As stated previously, I have brewed Ales. Without the bread idea, my next brew was to be a Belgium, hence the choice this time. Since I’ve got my equipment dialled in, I thought water would be my next thing to check so I brought some PH test strips, and also some iodine to test if I’m converting all the starch. As you will see, it would have been useful if I had done this on my previous brews so that I would have a comparison. However that will have to wait for next time.

- I not going to detail here every step. Just the main differences from the post before. I did an Iodine test at 60 min mash time and the test came out Black, a quick Google and at 68c the enzymes should have done their science by now. But going up to 90mins shouldn’t cause too many issues. I had a little stir and the temp had dropped to 64c. Even with 7kg of grain/bread, and 16l of water, the mash was very thick. I added a little water and brought the temp up a little and closed the lid and gave it another 30 mins.

-

Adding the mash water - I tested iodine again. This time it wasn’t black but still not a clear test. I decided that 90 mins was long enough, otherwise I may run into other issues.

- The drain of the mash was very slow. But I persisted and got a out 8.5 l of wort at a Brix of 18.

- Next I added the sparge. I added I couple of l of extra water, thinking the bread would hold more than the grains traditional 1l ish of water per Kg. when I went to drain the sparge water. Almost nothing, I checked that pipe wasn’t blocked, still nothing. The mash had a jelly like quality. Water just sitting in the grain refusing to budge. The solution was to dip a measuring jug in the grain and take it out 2l at a time and pour it through a hastily assembled 4 kitchen sieves. The result was the cloudiest wort know to man. The Irish Moss has got its work cut out.

- The rest went as planned. However, there is about 5–6l of water missing somewhere. 12 hours later the yeast is firing on all cylinders. I’ll do a bit of Googling and see about cloudy fermentations. But if all else fails I’ll leave it alone. “Don’t make the problem worse by guessing” someone clever then me once said.

- Once I made some sausages and put to much pepper in, I called them pepper sausages and everyone loved them saying, “you can really taste the pepper, lovely.” Maybe I’ll name the beer myCloud.

- Conclusion. We will see what the beer tastes like. If it’s good and/or has potential then it will be worth trying to get around the water refusing to budge issue. The solution needs to be simple, easy-ish to carry out. After all brewing is supposed to be fun.

- Random thoughts going forward.

Hastily prepared filter system

- Get a centrifuge with a high tech filtering system. - not going to happen.

- Filter the water through coffee type filters. - Brewing is supposed to be fun, and this would be a ball ache.

- Extract the starch from bread, then add that to the mash tun as part of the mash water. - is this possible?

- Keep the bread separated form the grain in the mash ton. Keeping the bread on top, then using the grain to filter the bread water.

- Put the bread in a brew bag. When draining the ton, remove the bag, drain separately, add the bread water back to the tun and use the grain to filter.. - maybe getting there with this type of solution?? Post mash Temperature control will be shot to pieces. Would this matter?

|

| Having to scoop the water out by hand |

- www.breadaddiction.co.uk

- www.getbrewing.uk

- www.beerproject.be

- www.toastale.com

Beer from bread recipe Spacial B was replaced by CaraAroma

Friday 29 January 2016

Thursday 28 January 2016

Full mash homebrew basic process, batch sparge

Wednesday 27 January 2016

My homebrew full mash equipment

Subscribe to:

Posts (Atom)